In recent years, the issue of power battery recycling has become a critical challenge for environmental protection. Illegal dismantling of lead-acid batteries and improper disposal of battery solutions are still prevalent, creating significant hurdles for formal recycling companies. These companies face issues such as low profitability, limited market size, and an inability to achieve economies of scale. Despite these challenges, the industry is at a crucial stage of development, particularly with the growing demand for power batteries in electric vehicles.

The current power battery processing market, especially for lead-acid batteries, is experiencing rapid growth. While safe recycling methods are still being explored, the peak of battery scrap is expected to arrive soon. For companies that have developed core technologies for recycling, this presents a unique opportunity. Not only can they prevent waste at the source, but they can also capture a larger share of the recycling market. However, the main challenge lies in curbing illegal secondary battery recycling activities.

Looking ahead, the Chinese auto market is set for a major transformation. According to Vice Minister Xin Guobin from the Ministry of Industry and Information Technology, the transition to new energy vehicles is accelerating, with 2025 marking a pivotal year. Industry forecasts suggest that the compound annual growth rate of new energy vehicle sales will exceed 30% over the next five years, directly boosting the demand for power batteries.

In 2016, China’s power battery output reached 64.5 billion yuan, surpassing traditional lithium-ion batteries for the first time. As lithium batteries replace lead-acid batteries as the preferred choice for electric vehicles, the recycling landscape is shifting. The first batch of lithium-ion batteries entered the market around five years ago, and by 2018, they will begin to reach the end of their life cycle, ushering in a wave of scrap.

According to research, by 2020, the amount of scrapped power batteries in China could exceed 248,000 tons—20 times the volume in 2016. This massive number poses both an environmental risk and an economic opportunity. Wang Binggang, head of the national new energy vehicle technology innovation engineering group, warned that poor handling could lead to a new environmental disaster. Recycling not only addresses pollution but also recovers valuable metals like cobalt and nickel, supporting the sustainable development of electric vehicles.

The potential for the recycling market is huge. By 2020, the value of recovered materials such as cobalt, nickel, manganese, lithium, and iron could exceed 10 billion yuan. Companies like Guangdong Bangpu have already demonstrated the viability of this model. Through their own recycling systems and partnerships, they extract raw materials from used batteries, which are then reused in the production of new ones. This process, known as “directed circulation,†reduces costs and supports long-term growth.

Government officials have also taken notice. At a recent forum, Ma Rong, deputy director of the National Development and Reform Commission, emphasized the need for all automotive and battery manufacturers to implement extended producer responsibility systems. He called for collaboration with recycling companies to prepare for the coming peak in battery scrap.

Despite progress, challenges remain. Many companies lack the necessary infrastructure and expertise to handle battery recycling effectively. There is a need for a comprehensive recycling system, standardized regulations, and a strong national research center to support the industry's growth. In addition, policies must be strengthened to prevent waste batteries from falling into the hands of unregulated or illegal operators.

Japan offers a useful model. Since 1994, Japanese battery companies have established a closed-loop recycling system, allowing consumers to return used batteries for free at retailers, car dealers, and gas stations. Major automakers like Toyota and Honda have also invested in advanced recycling technologies to recover valuable materials from hybrid batteries.

While subsidies may provide short-term relief, long-term sustainability depends on self-reliance. Companies must develop independent capabilities rather than relying solely on government support. Additionally, the illegal secondary battery market remains a serious concern. Online searches reveal numerous companies offering high prices for old batteries, but few disclose how they handle them. Some even refuse to explain or provide directions to their facilities.

To address these issues, stronger legal frameworks are needed. Policies should include binding regulations, strict enforcement, and incentives for responsible recycling. Germany’s deposit system for hazardous batteries serves as a good example, where consumers pay a deposit when purchasing batteries and get it back when returning used ones.

As the power battery recycling industry continues to grow, it is clear that both environmental and economic benefits are at stake. With proper regulation, technological innovation, and public awareness, the industry can move toward a sustainable future.

Discover the OREMA Solar GEL Deep Cycle Batteries, engineered with cutting-edge technology and rigorous quality assurance processes to deliver unparalleled performance and reliability. These batteries, featuring special separators and silica gel, are the epitome of innovation in the lead acid battery market.

Key Features of OREMA Solar GEL Battery:

1. Advanced Silica Gel Technology: OREMA uses silica gel to immobilize the electrolyte, enhancing cycle life and performance across a broad temperature range. This technology offers a 50% longer cycle life compared to standard AGM batteries.

2. Environmentally Friendly and Maintenance-Free: With their non-spillable construction and environmentally friendly design, these batteries require no maintenance, making them a hassle-free choice for users.

3. Wide Operating Temperature Range: Functioning efficiently between -20°C and +60°C, these batteries are designed to withstand extreme conditions without compromising performance.

4. Safety and Reliability: Features like explosion-proof construction, valve regulation, and high discharge rate capability ensure safety and dependability.

5. Efficient Energy Storage: Low self-discharge rates and ease of shipment make these batteries an ideal choice for various applications.

6. Convenience and Versatility: No need for balanced charge or boost, and no memory effect, ensuring ease of use in diverse settings.

7. Certified Quality: Adhering to stringent ISO quality management systems, OREMA has earned certifications like UL, CE, IEC, and ROHS, affirming its superior quality.

2. Environmentally Friendly and Maintenance-Free: With their non-spillable construction and environmentally friendly design, these batteries require no maintenance, making them a hassle-free choice for users.

3. Wide Operating Temperature Range: Functioning efficiently between -20°C and +60°C, these batteries are designed to withstand extreme conditions without compromising performance.

4. Safety and Reliability: Features like explosion-proof construction, valve regulation, and high discharge rate capability ensure safety and dependability.

5. Efficient Energy Storage: Low self-discharge rates and ease of shipment make these batteries an ideal choice for various applications.

6. Convenience and Versatility: No need for balanced charge or boost, and no memory effect, ensuring ease of use in diverse settings.

7. Certified Quality: Adhering to stringent ISO quality management systems, OREMA has earned certifications like UL, CE, IEC, and ROHS, affirming its superior quality.

Applications of OREMA Solar Deep Cycle Gel Battery:

- Communication and telecommunication control equipment

- Emergency and security systems, including fire and alarm systems

- Electric power systems, including power stations and nuclear power stations

- Renewable energy systems like solar and wind power

- Marine and medical equipment

- Uninterruptible power supplies

- Emergency and security systems, including fire and alarm systems

- Electric power systems, including power stations and nuclear power stations

- Renewable energy systems like solar and wind power

- Marine and medical equipment

- Uninterruptible power supplies

Why OREMA Solar Deep Cycle Gel Batteries?

With over 20 years of industry experience, state-of-the-art equipment, and 12 automated production lines, OREMA is dedicated to delivering perfection to its clients. Our customer-oriented approach and understanding of client needs have propelled us to a prominent position in the global lead-acid battery market. We offer OEM, ODM, and advanced customization services to over 80 countries, ensuring fast delivery within 30 days for in-stock products.

OREMA GEL Batteries represent the pinnacle of solar gel battery quality in China. Choose OREMA Solar GEL Deep Cycle Battery Series UNG for a reliable, efficient, and environmentally friendly power solution. Contact us for more information or to place your order today!

OREMA GEL Batteries represent the pinnacle of solar gel battery quality in China. Choose OREMA Solar GEL Deep Cycle Battery Series UNG for a reliable, efficient, and environmentally friendly power solution. Contact us for more information or to place your order today!

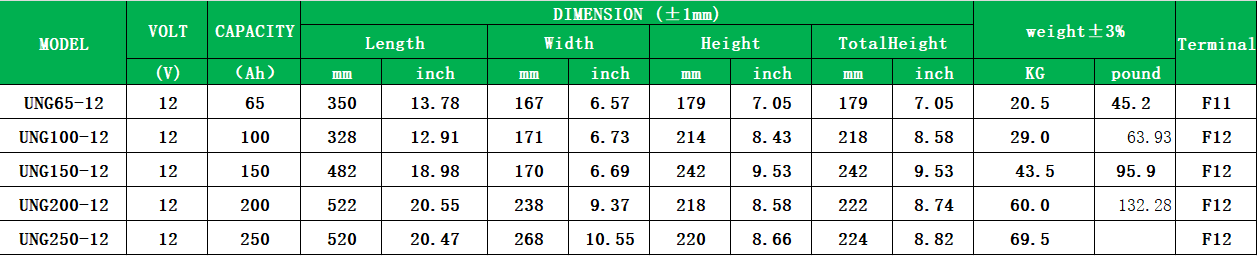

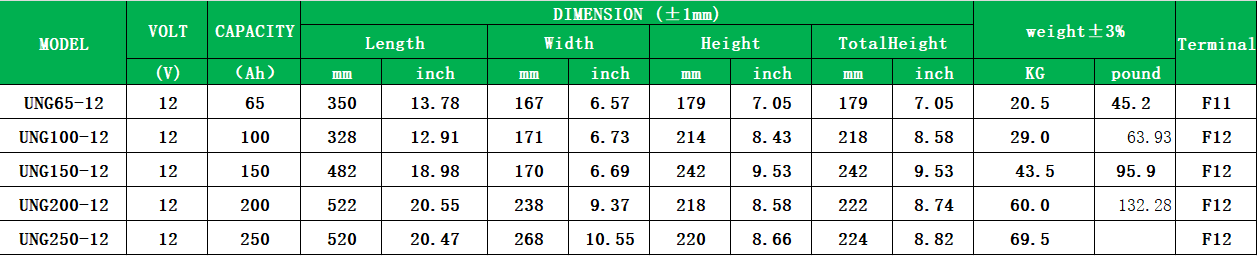

OREMA Solar GEL Deep Cycle Battery series GEL batteries specification table

12V Solar GEL Deep Cycle Batteries,solar gel battery,Gel Batteries,deep cycle gel battery,telecom battery,inverter battery

OREMA POWER CO., LTD. , https://www.oremapower.com